Features

Reduce Overages

Protection & Precision

Release Parameters

Flavor and Odor Masking

Effectiveness & Ease of Handling

Advantages of Microencapsulation

Protection of active from degradation

Protection of active from degradation Reduce evaporative loss

Reduce evaporative loss Shelf life enhancement

Shelf life enhancement Handling liquids as solid

Handling liquids as solid Handling of toxic materials in safe and convenient way

Handling of toxic materials in safe and convenient way Masking of odor and taste

Masking of odor and taste Immobilization of enzymes and microorganisms

Immobilization of enzymes and microorganisms Sustained, controlled and targeted delivery or timed release

Sustained, controlled and targeted delivery or timed release Better processability (improving solubility, dispersability, flowabilty)

Better processability (improving solubility, dispersability, flowabilty) Reduce plant stress and phytotoxicity

Reduce plant stress and phytotoxicity Reduce pesticide level in ground water

Reduce pesticide level in ground water Improve product utility

Improve product utility Easier to use

Easier to use Application flexibility

Application flexibility Lower use rate

Lower use rate Enhanced performance

Enhanced performance

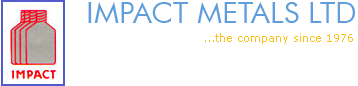

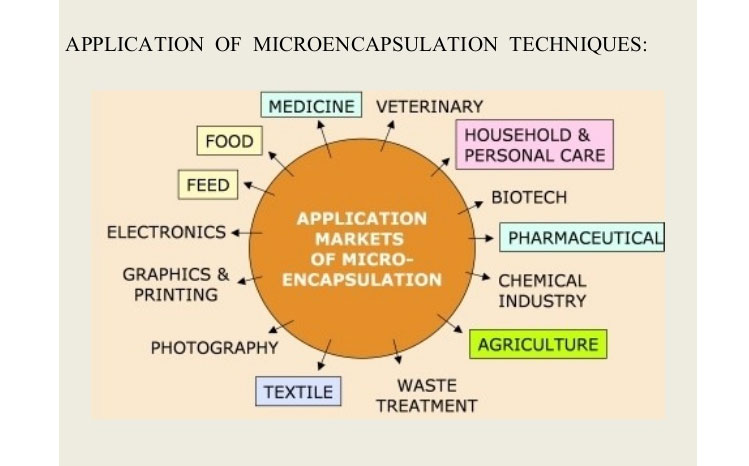

Microencapsulation is defined as a technology of packaging solids, liquids or gases, obtaining as a result thereof tiny particles or droplets surrounded by a coating, called microcapsules. In a relatively simple form, a microcapsule is a small sphere or fiber of an active substance container (diameters are between a few micrometers and a few millimeters) with an uniform, micro-porous and semi-permeable wall around it. The material inside the microcapsule is referred to as the core, internal phase, or fill, whereas the wall is sometimes called a shell, coating, or membrane. These microcapsules are inserted into final products to get the added-value that makes the difference respect to the competence. Thanks to the microencapsulation, several developments are getting to enhance products that are now already fully developed but currently require improves that the microencapsulation can provide.

Microencapsulation is defined as a technology of packaging solids, liquids or gases, obtaining as a result thereof tiny particles or droplets surrounded by a coating, called microcapsules. In a relatively simple form, a microcapsule is a small sphere or fiber of an active substance container (diameters are between a few micrometers and a few millimeters) with an uniform, micro-porous and semi-permeable wall around it. The material inside the microcapsule is referred to as the core, internal phase, or fill, whereas the wall is sometimes called a shell, coating, or membrane. These microcapsules are inserted into final products to get the added-value that makes the difference respect to the competence. Thanks to the microencapsulation, several developments are getting to enhance products that are now already fully developed but currently require improves that the microencapsulation can provide.

The reasons for microencapsulation are countless. It is mainly used to increase the stability and life of the product being encapsulated, facilitate the manipulation of the product and control its liberation in an adequate time and space. In some cases, the core must be isolated from its surroundings, as in isolating vitamins from the deteriorating effects of oxygen, retarding evaporation of a volatile core, improving the handling properties of a sticky material, or isolating a reactive core from chemical attack. In other cases, the objective is not to isolate the core completely but to control the rate at which it leaves the microcapsule, as in the controlled release of drugs or pesticides.

The definition has been expanded, and includes most foods, where the encapsulation of flavors is the most common. The technique of microencapsulation depends on the physical and chemical properties of the material to be encapsulated.